Product Maintenance | How to Install Your La Marzocco Linea Mini Plumb In Kit

The Linea Mini Plumb In Kit has all the parts needed to convert your La Marzocco Linea Mini reservoir machine to a plumb in version. Interested in transforming your machine? See the process from start to finish in this video, as Steve demonstrates adapting a Linea Mini with the complete plumb in kit.

Transcript

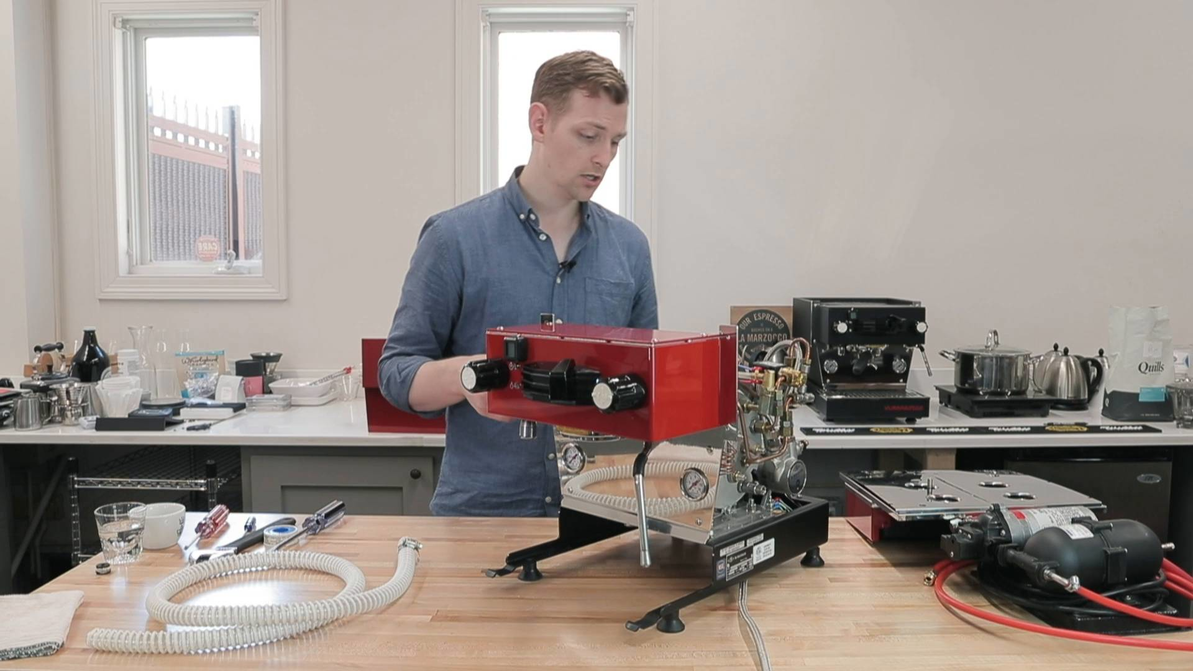

Hey guys. It's Steve with Prima Coffee. Today we're going to take a look at how to plumb in a Linea Mini espresso machine. So the Linea Mini comes with a built-in reservoir as well as an unplumbed drip tray. However, it can be converted through the use of a plumbing kit, to be plumbed directly into either a boost pump on a bottle for a catering setting or something like that, or to actually plumb directly into your main drain in a house and a coffee shop, that sort of thing. It's a fairly simple conversion, but it does require kind of a bit of a process. So we're going to walk you through all of the steps, as well as take a look at what comes in that plumbing kit. So what you're going to need in terms of tools, you're going to need some Teflon tape to seal things up, an adjustable wrench, you're going to need one slotted screwdriver, and that's mainly for these front screws. So you can just kind of gauge what size you need based on the front screws there. And you're also going to need a couple different sizes of Phillips-head screws.

La Marzocco Linea Mini Plumb In KitConverts Linea Mini reservoir machines to plumb in version

Featured Product

I would recommend that if you have it available, use a Phillips screwdriver with the longest actual driving rod as possible, because there are some screws in the back of the chassis that you have to loosen and it's a little bit hard to get access to them. If you have a longer one, it's a lot easier. So you need two different sizes. One is to actually take some of the screws off of the body and the chassis here. We also have a very small screw on this part, I'll get to it a little bit later, but you need a smaller Phillips-head for that, just so you don't strip it. So we don't need too much in the way of tools. Pretty simple, widely available stuff. And you get most of what you need already here in the kit. So what I have is my new, braided, stainless steel, inlet hose. I've got a nice, long drain hose as well along with a hose clamp for it. And then, I have these two parts. These are for converting the drain box to run this drain line.

We have just the actual fitting itself that replaces the plug, and then we have sort of a sleeve that goes over that. You can see we have these three O rings here, along with the barbed fitting for the hose itself. And finally, we have this little guy, so because the Linea Mini has an autofill, or actually a reservoir fill sensor, this is respectively a jumper. What it is, is it's going to bridge the two spring contacts, which I'll get to a little bit later toward the end of the process, and you're going to need to screw it in place, covering both of those contacts. It's a little bit of a tight squeeze, but it's fairly easy to screw in. There's an existing hole there anyway. So, let's get right into it. What I've done already is I removed some screws from underneath the cup tray. Everything else is still fairly intact. The first step that we have here is we're just actually going to take the drain box out and if you want to plumb this in and actually run it to a drain, that's the first step that you'll take.

So, we're just going to get a big slotted screwdriver and undo this plug. Really easy. It's only about three-quarters of an inch long. Super easy to take out. And then, we're going to take that fitting, screw it into place. You might want to use some Teflon tape here. It's not totally necessary. It's a low pressure area anyway. If you do experience some leaks, it's pretty easy to access and get some tape on there if you need to. So, we're just going to use our adjustable wrench and tighten that down. At this point, I'll probably also put on my sleeve with the barb. What I'm going to do is I've just got some water here. I'm going to wet the O rings, just so it's easier to get it on, and I'm also going to rub just a little bit of water on the inside of the sleeve. And that's just a push fit, so push it on, takes a little bit of leverage. It's nice and secure. And from there, our drip tray is basically done. We're not going to put the hose on yet, just because we need to get a little bit more access here where currently the water reservoir is.

So, I'm going to set this aside and we're going to go onto the next step, which is to remove the cup tray itself. Again, I've removed all the screws here just for simplicity, but you would take all the screws out and that is all the screws. Often, in order to remove this piece itself, you would leave one of the screws here to keep the computer attached, but we actually need that disconnected from the body, the whole sort of back body panel itself. So, we're going to disconnect that as well. Again, we'll just take this and set it aside. Now internally, there are two further steps that I need to take. One is to remove, there's the PID dial over here. If you're looking at the left side of the machine. We need to actually disconnect that and pull that through, so that involves, I would say taking some needle-nose pliers. It's a little bit harder to access. I mean, if you have a socket set or something that might be able to access those, just two nuts and they only need to be loosened. They don't need to be removed.

Once they're loosened, we're able to pull up on the PID control wheel, pull it up and pull it up vertically, and then backwards a little bit. Once it's cleared, there's a little screw in there as well. We don't need to disconnect anything here. You can see I have it free in my hand now. I'm just going to set it just on top of the machine. I should obviously stress that this machine should be cold when you're doing this bit of maintenance. We don't want it to be hot. Obviously, that's going to be uncomfortable as you're working internally inside the machine. But, we also want it to be depressurized and not hooked up to water or anything. So, nice and cool is the best way to work on it. The next thing that we're going to do is we're going to loosen these two screws in the very back corners of the machine, all the way back here. There's one on each side. They're both Phillips-head. This is what I was talking about, that it's fairly kind of tight, enclosed. There's some plumbing in the way. It can be a little bit hard to reach. So the longer the stem on your Philips- head is, the easier time you're going to have.

I've actually already pre-loosened these, so I don't need to do anything. You don't need to take them out. You just need to loosen them a couple turns because what you're going to do is you're going to slide the body backwards once you have these front screws free. So, the next step is to just remove these front screws. So, I've got my slotted screwdriver and I'm just going to take these guys out. They're not too long. They're really just holding that body panel on. one thing you might want to take care of though is, you know, don't let your slotted screwdriver slide around too much. You don't want to scratch up that beautiful polished stainless or your paint job. So, there's just four screws. We're going to do the top left and right, and then the ones immediately below it. We don't need to remove any other screws. There obviously are a whole bunch of other ones, but they're holding on different components inside the machine. So, that's two done. These other guys.

So, once we have these four screws free, we're able to slide the entire back and side panels off. It's all one unit in a C- shape. We do want to be careful though as we're doing that, to just to make sure that we're not, you know, dragging it along any of the components inside the machine. It's a fairly tight fit in there, you know, it's a pretty well-optimized space and it's not completely clear as you're pulling this machine off, or the panel off, sorry. It takes a little, tiny bit of care just to make sure that everything is staying out of the way and you're not cutting anything or bending anything. So, I'm free to slide this back. I'm going to slide it back about an inch, and then I'm going to kind of flare these bottom corners out, just so I have a little bit more clearance as I'm pulling things back. As you can see, I'm being a little bit careful just to make sure I stay clear of all the components in there. So, now we have access to the internals of the machine. I'm going to turn it for you.

What we need access to specifically here is the actual pump itself. Our reservoir intake hose, or I'm sorry, the pump intake hose from the reservoir is right here and you can see it's connected to the inlet for the pump itself. So, what I need to do is remove that fitting, and I'm going to use my adjustable wrench to do that. So, just a couple of turns. It's pretty easy to remove there. It's free. So, what I'm going to do is I'm going to hold onto this end, I'm going to slide the reservoir forward, and I'm going to kind of feed it through. There's a hole on the underside here. You can see it. I'm going to feed it through, and then because that piece of copper piping is curved, you want to kind of snake it through to make sure that it goes along that curve. Takes a second to figure that out. So, there we go. We're free. We have the reservoir out. We can set that aside, you know, somewhere for safe keeping, because we don't need it for the rest of this process, and if we're plumbing it in, we're not going to need it anyway.

Now from here, we're going to start to work backwards. We're going to take our braided steel line and we're going to feed it through that same hole that we just pulled the reservoir line through. Now, finding a position for this , it doesn't have that sort of elbow to it. Finding a position for this is perhaps a little bit tricky. What I have found seems to work pretty well is to kind of snake it in between some of the existing tubing here, and then back around or back, sort of through itself, just so you can have a good access to that fitting there, just kind of finger tightening it here. It's a little tight. Just kind of trying to make it...there we go, thread on. There. We don't want to kink this hose. We want to make sure that it's got a good sort of gentle bend to it. We have that part done and we can just sort of set this hose aside for now. We're not going to quite tighten it yet. We'll do that before we put the body panel back on.

The next step is to put on this jumper. And to do that, I don't know that we'll be able to get a good shot of it, because it's a pretty tight space. I can rotate the machine just to show you where this fitting is. If you look right down here, there's two springs and those springs need to be connected by this piece of metal. So, what I'm going to do is I'm going to screw this screw directly into, you can see there's a little bit of a hole in there, I'm going to screw that into place, nice and firmly, make sure that this metal is making good contact with both springs, and you don't really need to tighten it all the way down. You just need to make sure that it's nice and firm and pushing a little bit on the springs so that you're making a connection between the two. Again, that's just to make sure that the machine knows that there's water. Typically, inside the reservoir, you can see here we have these two contacts that stick into the reservoir a little bit.

So when water is above this top contact, it's allowing an electrical connection to flow between those two contacts. As it falls below that one, the machine says, "Hey, my water's a little bit too low. I don't sense a connection between these two anymore," and it'll blink a blue, flashing light to let you know you need to fill your reservoir. Obviously, we don't need to worry about the reservoir anymore, so we're telling the machine, "Hey, we've always got water." I'm just going to try and install this. Okay. So, we've got that jumper installed in there. It takes a minute. Again, you just need to make sure that it's contacting both those springs and tightening down enough that it's going to stay contacting both those springs. From here, we're going to make sure that we tighten our actual connection on the pump. So, just want to make sure that it's nice and snug, and this is actually another step where you might want to use some Teflon tape.

The hose itself is actually designed for this pump and fitting. But as it's a higher-pressure connection, you might want to use a little bit of tape on the threads, just to seal everything up and make sure there are no leaks. Now, optional and this is possibly something most people won't actually want to mess with, but right here is your flow adjustment for the pump. So, if you want to set your brew pressure a little bit lower on the Linea Mini, ours is actually currently set at around six bars, you would do it right here. So, you have a little black nut that you loosen, and then you can play with this screw to actually adjust that pressure. Ideally, you're going to need to do that after it's hooked up to water and while it's running so you can actually live see what you're adjustment is doing to the pressure. But, just for actual reference, that screw is right there. Now again, we're going to kind of work backwards from here and we're going to start reinstalling parts.

So, we are ready to actually hook it all up to our lines and everything. So, I'm going to grab the back panel again and start to get it situated. There are two things you need to note as you're installing this back panel again. There's a little screw right here and a corresponding hole on the front of the panel itself. You need to make sure that that gets fed into that hole. And then obviously, we have our back screws here, which need to slide into slots on the bottom side of the panel. So, just as before, we're going to kind of carefully slide everything back into place, taking care not to smash into pipes or cut any wires or anything like that. So, just kind of carefully proceed, lightly nudge things out of the way as necessary, and then again, we're going to make sure that this pin screw down there is aligned with that front hole, and slide it in. We're just about there. There we go. Okay.

Now from here, we are going to reinstall those four slotted front screws, followed by tightening the two screws in the back that we loosened. So, just as before, just four screws. I like to alternate the top ones first because they help align the other screw holes. You might need to kind of push things around just to make sure the alignment is correct. There we go. And I just start by finger tightening because it's a little bit easier to get started. I'm actually going to tighten these down, probably like, three-quarters of the way, just until they're a little bit snug. Again, that's just to help align the other two holes that I have to feed screws into. Okay. Once we have all four of these screwed in, and I like to do these first, obviously because I'm working in reverse according to what our instructions actually told us. But, it's also a little bit easier to do this part when the body panel can kind of slide around just a little bit, as you need to make slight tweaks.

So, if those two screws in the back were already fully tightened down, it would be a lot harder to make the adjustments that you need in order to make sure all of your front screws are aligned properly. So, now that I've got them all in, I'm going to go back and tighten everything, and they don't need to be horribly tight. They're mainly there just to hold that panel in place and during normal usage, it's not really shifting around anywhere. And now, I'm going to get in here. Again, it's pretty tight, but all I need to do is give these guys maybe a turn or two, just to kind of make sure that the panel is held down nicely. So, here we go. Okay. Everything's nice and tight. Now we're ready to get the PID wheel connected again.

We're basically going to do it in reverse of what we did before. We have a large hole here that feeds into the upper cover, like, slides over the nut, and then once it's all pushed against this side, you can slide it straight down. There we go. You also want to make sure, of course, that the wheel is poking through the slot in the body panel itself. And finger tight, honestly is good enough for these two nuts, as long as you can, you know, get in there with your fingers. You know, you don't really push too hard on the wheel itself. If you want to go in with a pair of pliers, that's the easiest, some needle-nose pliers is the easiest way to kind of get purchase on those nuts and tighten them down. But, I find that finger tight is good enough and doesn't really go anywhere. So, just make sure that it's well aligned. You'll have probably adjusted your dial, so you might want to make sure that it's back on the right temperature.

And finally, we're going to take our computer box and we're going to hook that back up. We need to put in one screw before we get the top cover back on. So, I just have one screw and it goes here on, again, if you're looking at the front of the machine, the back left side. And we'll just feed that in. It's a little tricky to get started, because the box itself, the whole shell is kind of free floating. But, once you get those first couple of threads in, you can just tighten up that screw. One thing you want to make sure of, of course, is that the opposite screw hole is aligned up with the hole in the frame itself. Now, we can get our back cover on. Our top cover on, rather. So, we've got that first screw in there. We're just going to screw everything else back down. I like to start with this back middle screw, because it aligns with the hole in that computer box. So, that's the best way to kind of make sure that everything is nice and secure from the start, and from there, actually I find it's a little bit easier to actually get the side holes screwed down as well, because you've already got that middle, sort of pin down, and then you can work on the other screws.

From here though, we're basically done with the conversion. We're essentially just kind of putting all the cosmetic stuff back together. The machine itself should be ready to start hooking up to your mains water. So, perhaps we should talk about at this point, what you'll actually need to hook up the water line on this machine to. I did mention that, you know, in certain catering settings or farmer's markets, maybe you want to run it on a water bottle, like, a five gallon jug or maybe a jerrycan or something full of water, just so you have access to more water. You don't have to worry too much about constantly refilling while you're doing service at an event or in a mobile situation. So, if you do want to hook up that water line, you might have a pump like this. So, this is a sort of mobile sure-flow pump with a small pressure accumulator on it. So, we have the pressure accumulator here, we have the pump right here. This big line will feed into your water bottle. You just set it all the way down in the bottom of the bottle, and then we also have the small line here feeding off the accumulator will hook up to your braided water line.

In this case, we've already got a compression fitting on it, but you could connect your line actually as we have, to a push fitting, called a John Guest fitting. So, you just make sure that this is the same size as your plastic, flexible line here. So then, you could just push fit them together and you're all set. Really, really easy to set up. You do need electricity for a pump like this, which shouldn't be too bad in a lot of mobile settings. But, it is an extra requirement. Usually, they're a 120 volt, just like the machine is. But, you can also, of course, hook it directly up to mains water. We do recommend hooking it up to filtered water, of course. La Marzocco has water specifications included in the manual. The machine, you'll always want to make sure that you're running the correct quality water for your Linea Mini, just to, of course, maintain warranty, but also protect the internals of the machine.

Now, our final step here, now that we have things assembled, obviously apart from hooking this up to water, we're going to be hooking up our drain hose to this barb. So, it's actually quite simple. Just push it directly into the barb. It's a little bit of a tight fit, so you want to make sure that you give it a lot of good force, and you want it to be fully seated onto there. And then, I'm just going to take a screwdriver and I'm going to loosen up this hose clamp just a little bit, so I can slide it further down. And once I've got it situated in place right over the barb, just to make sure everything is nice and leakproof, I'm going to then tighten it down quite firmly. Basically, about as tightly as I can go.

Leaks on a drain hose aren't super common, but you know, you do want to make sure that you're preventing leaks wherever possible. So, we're just going to tighten that hose clamp down nice and firmly. And from there, turn the machine back around for you again. So, now I've got a braided line. I can actually run that out the back side of the machine. Again, just kind of make sure that you're not kinking the hose. Give it a gentle curve as possible. And now, we can reinstall our drain box. Obviously, we want to run that drain hose somewhere. I'm just going to run it straight out behind the machine for now. If you're installing this somewhere, you probably want to run it down through a hole cut in your counter or directly to, like, a PVC tube for your actual drain line. But, you got plenty of clearance underneath to feed in. And then, it'll sit right nicely in place.

So, that was it. I mean, it's a little bit of a process, but fairly easy to do with pretty simple tools. Again, you just want to make sure that you're being careful with pulling the panel off, being careful with making sure that all of your fittings are nice and tight to prevent leaks. You do probably want to use some Teflon tape on some of those threaded connections, especially as they connect to the pump. But, overall a fairly simple process and a really easy conversion to running your Linea Mini on a plumbed water supply. So, that is the Linea Mini plumbing kit and how to install it on your Linea Mini. Thanks for watching.